Coatings in the infrared spectral range – protection of sensitive surfaces

The customer-specific and standard IR coatings from Jenoptik combine highest quality with maximum precision.

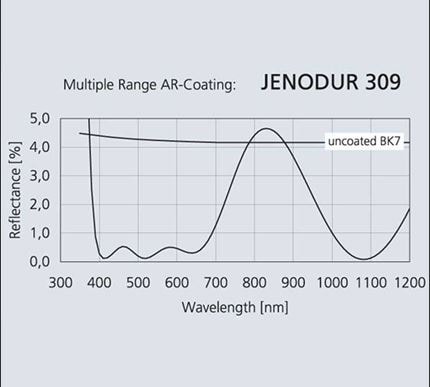

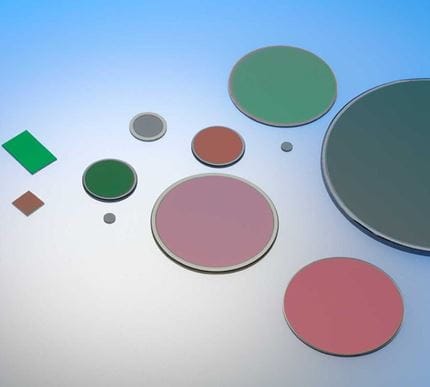

Infrared coatings protect your surfaces and are ideal for materials with specific, complex properties. We offer a wide range of infrared optical coatings in the wavelength range from λ1.5 to 20 micrometers. They are characterized by their high quality, durability and robustness, and can easily withstand even the harshest environmental conditions. They are also completely free of radioactive materials.

Jenoptik provides the following standard coatings:

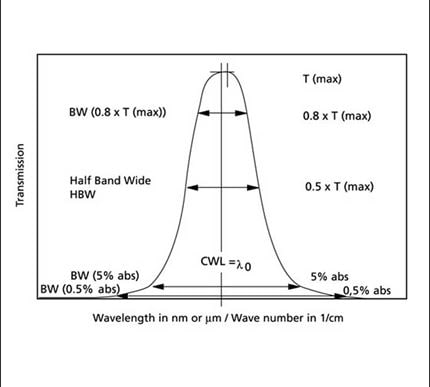

- Bandpass and narrow band filters

- Dual and triple-band filters

- Edge filters (long and short-pass)

- Multifunctional filters

- with anti-reflective coatings

In addition to the standard IR coatings, we can also provide custom solutions matching your specifications. We regularly control the quality of our coatings. We also work with an independent testing and calibration laboratory to qualify our optical components. We have extensive experience of the various test methods and will select the procedure most appropriate to your application. Testing is performed on the basis of all relevant DIN, IEC, EN and MIL standards, while the coatings themselves comply with the strict requirements of the standards MIL-C-48497 and MIL-F-48616.

The following tests – or combinations thereof – are possible:

- Optical parameter inspection: interferometric testing; aspheric testing with CGHs; transmission measurement up to temperatures of 95 K; MTF measurement in temperature range from 233 K to 333 K; wiper test for front faces with DLC coatings (based on TS1888).

- Testing for climatic stability subject to changes in temperature and humidity as well as temperature shock: determination of temperature and climate boundaries; realization of thermal stress parameters.

- Shock and vibration testing

Benefits

- Long-term stability: totally reliable

- Robust: able to withstand even the toughest environmental conditions

- Safe: free from radioactive materials

- Tested: regular transmission, reflection and durability tests

- Customer-specific: adapted to your individual requirements

Fields of Application

- Security technology: process and building monitoring, filters for gas analysis, mining, alcohol measurement, building technology

- Environmental technology: NDIR gas analysis/gas sensors for biogas analysis, greenhouse gas analysis or emission monitoring

- Medical technology: NDIR gas analysis for patient and anesthesia monitoring

- Agriculture: biogas plants, quality control

- Flame detection: pyroelectric detectors

- IR spectroscopy: chemical analyses, e.g. of alcohol, sugar and water content

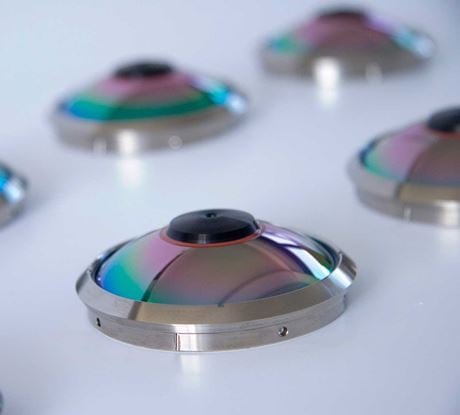

DLC and hybrid-DLC coatings for highly durable surfaces

Diamond-like carbon (DLC) layers reliably protect your infrared optical systems against the harshest environmental conditions. These coatings are highly robust and resilient.

Hybrid-DLC layers combine the benefits of classic DLC layers with the functionality of multispectral IR coatings. To safeguard the quality of diamond-like carbon layers in the long term, we subject them to regular testing in line with the directive TS 1888 P5.4.3. With hybrid-DLC coatings, you can better suppress interfering reflections than with standard DLC layers.

Hermetically solderable freeform filters

Downloads

Product recommendations

Components