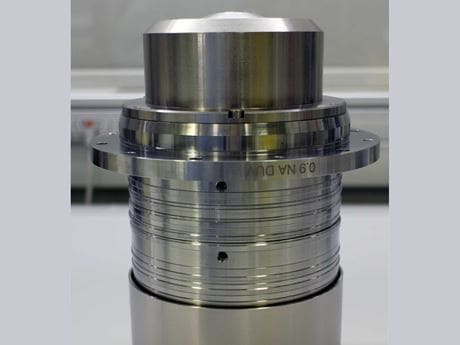

Highly Precise Adjustment of DUV Optics thanks to Patented Mounting Technology

Jenoptik developed a stress-free mounting technology for DUV optics as part of a project sponsored by Thüringer Aufbaubank (TAB). This technology holds optical elements without the need for an adhesive.

The patented mounting technology for optics compensates thermal stresses in optical systems. Jenoptik developed the technology specially for DUV optics with a high numerical aperture. The new concept enables optical elements to be set quickly, robustly and precisely to an accuracy of less than ten nanometers.

It is completely free of adhesives and uses stackable technology (stack-mounting). This reduces stress-induced birefringence and increases the stability of the optical components — the objective lenses perform even under the most demanding conditions.

The new concept means you can mount optical elements precisely: You can position them perpendicular to the optical axis at an accuracy of less than ten nanometers over a range of around 300 microns. This means you can adjust the optical elements in DUV optical systems very precisely and ensure they are well secured.

The Jenoptik technology funded by the Thüringer Aufbaubank as part of a project is used for optical material such as calcium fluoride and quartz glass and mounting materials such as stainless steel, aluminum and bronze.

With the wavefront measurement system, you can adjust and qualify the entire system quickly and accurately, saving you time and money. Jenoptik combines different measuring principles in one measuring system, which can be universally adapted — saving development time and costs.

It is completely free of adhesives and uses stackable technology (stack-mounting). This reduces stress-induced birefringence and increases the stability of the optical components — the objective lenses perform even under the most demanding conditions.

The new concept means you can mount optical elements precisely: You can position them perpendicular to the optical axis at an accuracy of less than ten nanometers over a range of around 300 microns. This means you can adjust the optical elements in DUV optical systems very precisely and ensure they are well secured.

The Jenoptik technology funded by the Thüringer Aufbaubank as part of a project is used for optical material such as calcium fluoride and quartz glass and mounting materials such as stainless steel, aluminum and bronze.

Universal Wavefront Measurement System Guarantees Quality

With the wavefront measurement system, you can adjust and qualify the entire system quickly and accurately, saving you time and money. Jenoptik combines different measuring principles in one measuring system, which can be universally adapted — saving development time and costs.

Benefits

- Patented: Specifically developed for DUV optics with a high numerical aperture

- Adhesive-free: Use stack-based technology (stack-mounting)

- Powerful: Offset thermal stresses in optical systems

- Extremely precise: Position optical elements with an accuracy of less than 10 nanometers

- Repeatability: Adapt technology for various optical materials

- Cost-saving: Set the entire system quickly with the wavefront measurement system

Fields of Application

- Semiconductor equipment: Beam control and lighting systems

- Flat-panel display industry: Micro-material processing

Product recommendations

Components

Do you have any questions? Our experts are happy to help.