RecommendMail Facebook LinkedIn

Blechexpo 2023: More efficient stamping production thanks to optical inspection with integrated laser processing

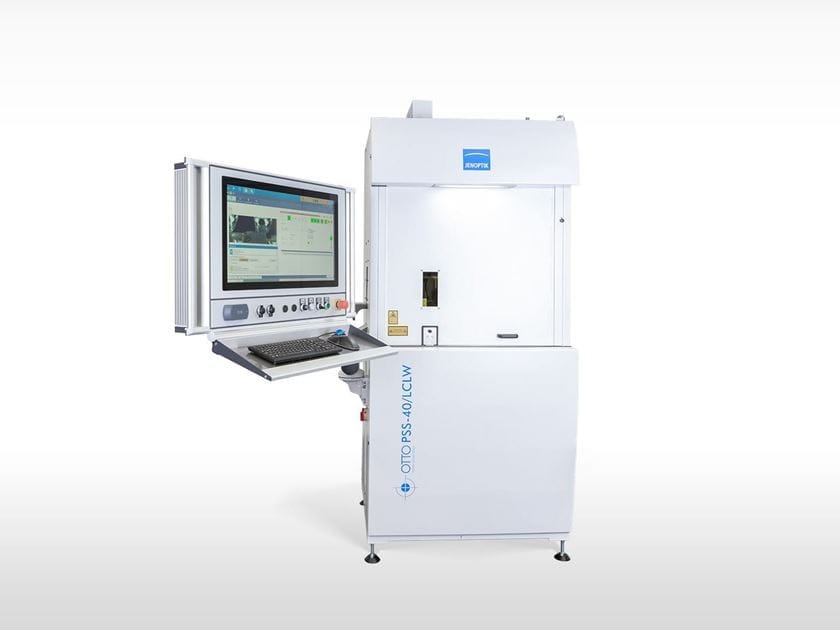

At the trade fair for sheet metal working, Jenoptik will be introducing its PSS-40/LCLW inspection machine, which optimizes the manufacturing of stamped parts thanks to integrated laser cutting and laser welding. First demonstrations at Blechexpo in Stuttgart from November 7 to 10, 2023 at the Jenoptik booth in hall 6, booth #6209.

In Stuttgart, Germany, the photonics group Jenoptik will present its PSS-40/LCLW inspection and sorting station. It enables automated optical inspection of punched strips as well as uninterrupted removal of defective parts in just one system thanks to cameras, software analysis and lasers. To this end, Jenoptik has further developed its PSS-40 standard inspection cell, which is already established on the market, and integrated fully automated laser cutting and laser welding into the inspection station.

Customers in the stamp industry can thus inspect strip goods without interruption or sort out rejected parts efficiently and fully automatically. In its compact, space-saving design, the new PSS-40/LCLW also reduces interruption times in the die cutting shop as well as the changeover times when changing articles.

Continuous improvement in the die cutting process thanks to “all-in-one” testing station

Jenoptik’s inspection stations enable 100 percent inspection of almost all metric and attribute inspection characteristics. The software developed in-house detects and marks parts that are out of tolerance so that they can be separated out in subsequent processes. Until now, the separation and subsequent joining of the carrier strip has been carried out by mechanical separation and thermal joining, which usually requires the manual or semi-automatic intervention of an operator – and a production standstill for several minutes.

The integrated laser processing in the PSS-40/LCLW replaces these manual or semi-automatic process steps and enables uninterrupted stamping. This is because the marked bad part is cut out by laser cutting without wear within the inspection station. The then loose ends of the punched carrier strip are also brought together with high precision within the PSS unit and reconnected by laser welding. Thanks to the flexibly adjustable laser beam and the free beam guidance, even component positions that are difficult to access can be reached. The welding result is verified by a fully automatic tensile test. The welded punched strip has a very high strength.

With the PSS-40/LCLW, Jenoptik is also nominated for the "best Award 2023" in category 4 (Stamping Technologies). The award for the biggest innovations at the trade show will be presented during Blechexpo on the first day of the show.

Visit Jenoptik at the trade fair in Stuttgart from November 7 to 10 at the Jenoptik booth in hall 6, booth# 6209.

Images are available for download in the Jenoptik image database under "Products".

About Jenoptik

Optical technologies form the basis of our business. Jenoptik is a global photonics group and comprises the two divisions Advanced Photonic Solutions and Smart Mobility Solutions. Non-photonic activities, particularly for the automotive market, are operated as independent brands within the Non-Photonic Portfolio Companies. Our key markets primarily include semiconductor & electronics, life science & medical technology as well as smart mobility. More than 4,400 people worldwide (fiscal year 2022) work for the Jenoptik Group, which is headquartered in Jena (Germany). JENOPTIK AG is listed on the German Stock Exchange in Frankfurt and traded on the MDax and TecDax. In fiscal year 2022, Jenoptik generated revenue of 980.7 million euros.